The electrode mesh produced by Qina HET demonstrates excellent performance, high decay resistance, and superior operational stability.

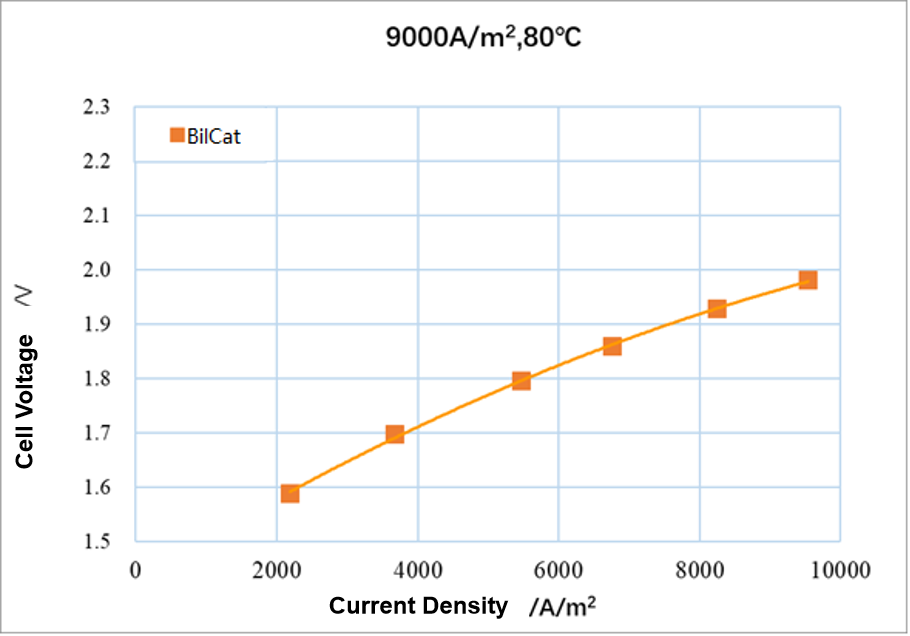

I. Performance in 2Nm3/h Electrolyzer

Operating Conditions:

Electrode dimensions: ø 160 mm

Electrolyte: 30% KOH (w/w)

Temperature: 80 ± 0.5℃

Electrolyte flow rate: 0.2m3/h

Key Metric:

Current density: ~5,700 A/m2 at 1.8 V

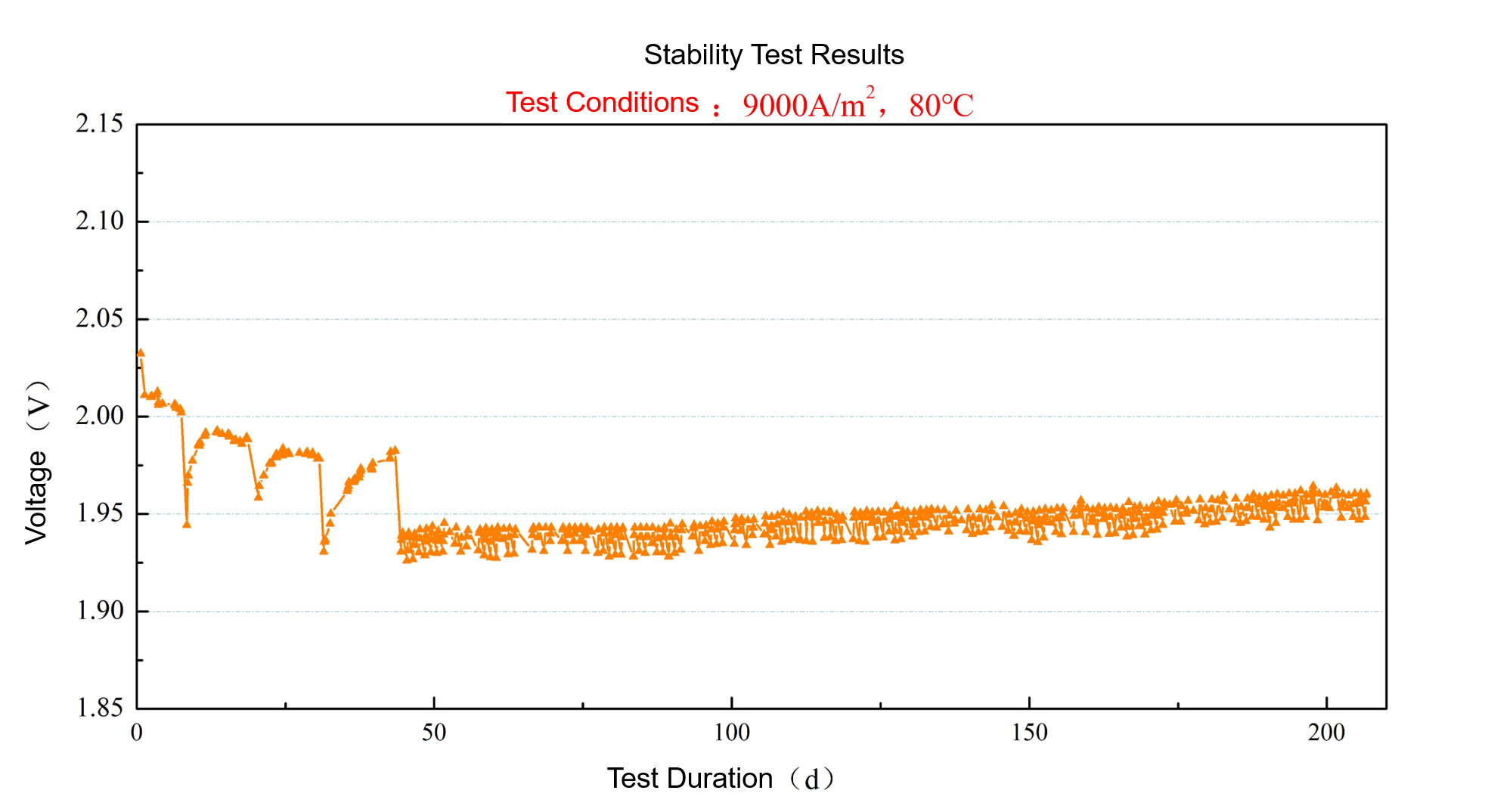

II. BilCat Stability Operation Data

Test Conditions:

Identical to 2Nm3/h electrolyzer operation:

30% KOH(w/w), 80 ± 0.5℃, electrolyte flow rate 0.2m3/h, electrode ø 160 mm.

Constant-Current Operation (45days):

- Current density: 9,000 A/m2

- Polarization curves measured every 7-10 days

Result: Performance decay over 1,000 hours.

Start-Stop Cycling Test (167 days):

- The mesh was subjected to cyclic testing at 9,000 A/m2 over 167 days,

with each cycle consisting of 12 hours operation followed by 12 hours shutdown.

Result: Performance decay 10μV/h over 4,000 hours.

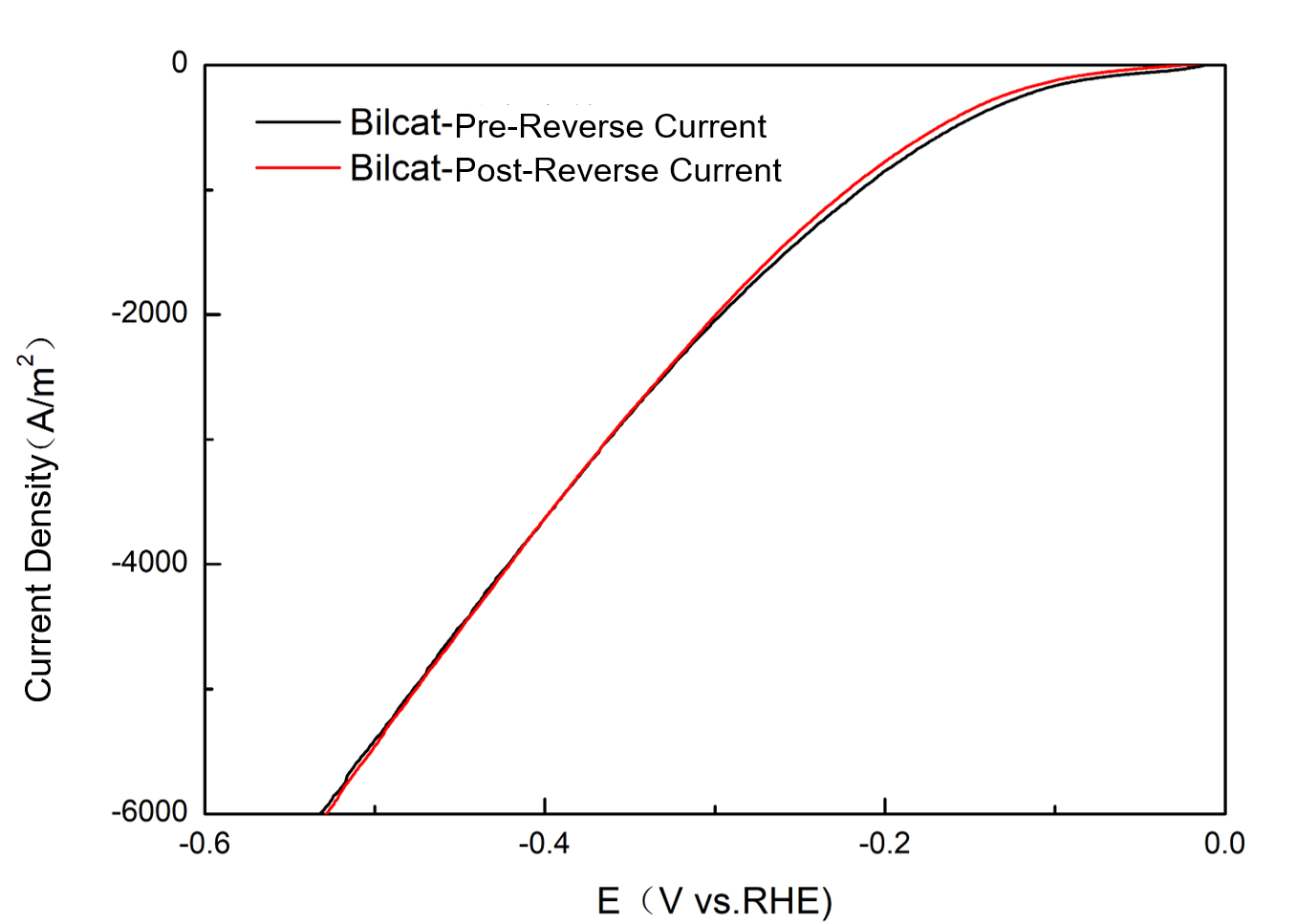

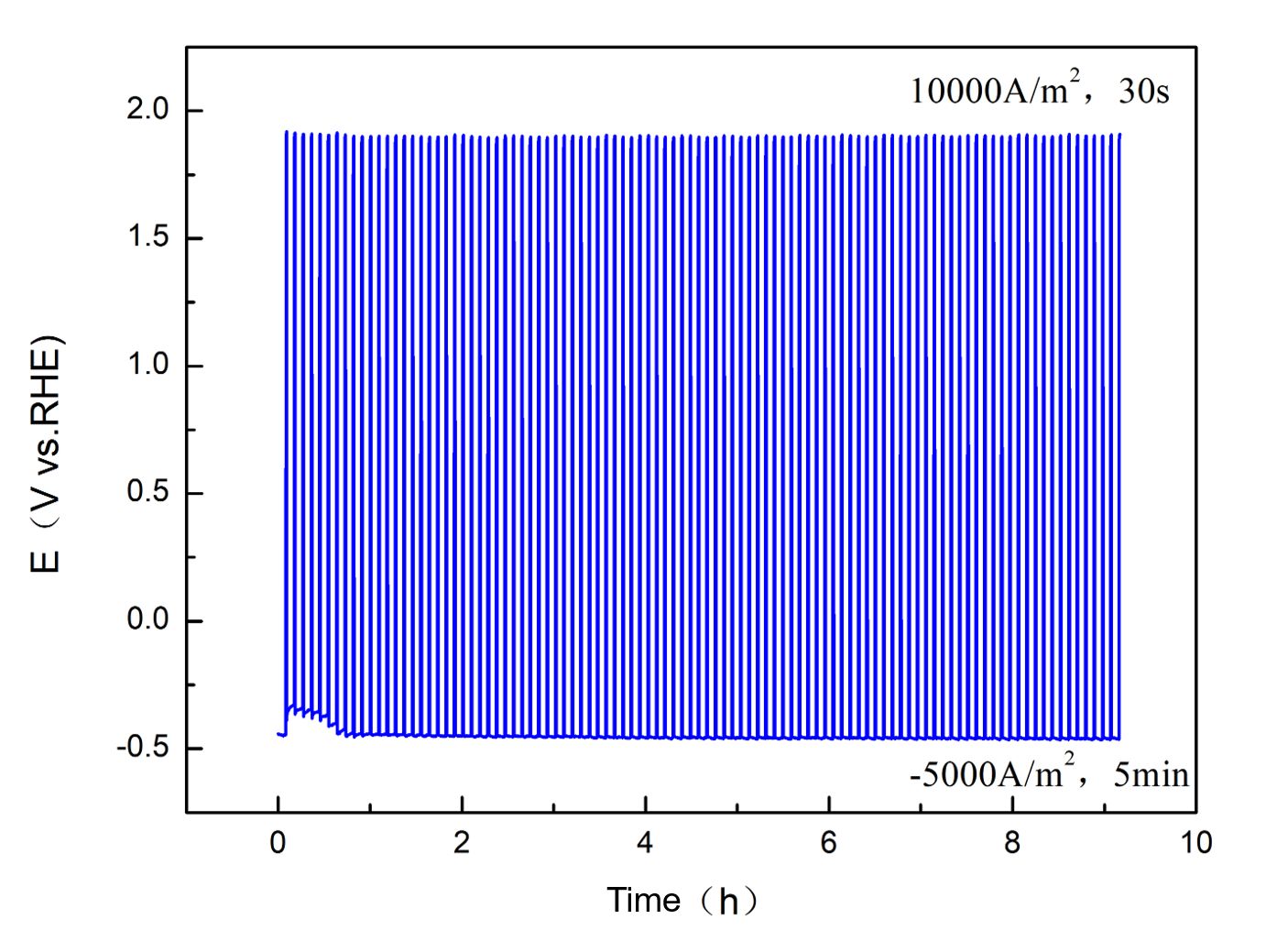

III. Reverse Current Testing

Test Conditions:

30% KOH (w/w), 80℃

Electrode dimensions: 20 x 20 mm

Cyclic Loading Protocol:

The cycle test comprised: +10000 A/m2 for 30 s followed by -5000 A/m2 for 5 min per cycle.

LSV curves were measured every 100 cycles.

Result: Performance decay after 100 cycles.